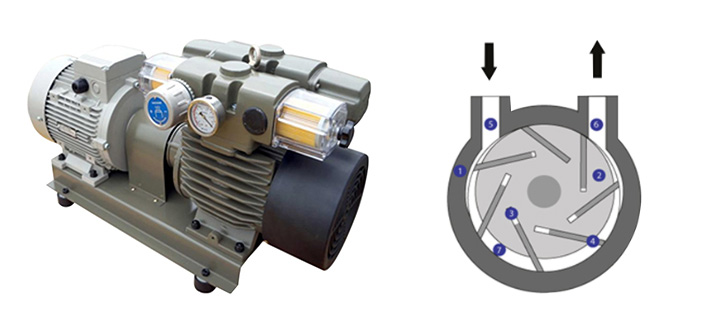

Dry Rotary Vacuum Pump

Rotary vane pumps consist of a cylindrical housing (1), eccentrically positioned rotor (2), and numerous free-moving vanes (4). The vanes are placed in the slots of the rotor (3) and, as the rotor turns, the centrifugal force throws the vanes against the cylindrical wall, creating a chamber between the rotor and the cylinder (7). The chamber volume changes as the rotor turns. From the inlet port (5), the chamber volume enlarges, and then decreases towards the outlet port (6). As air enters the inlet port (5) and the chamber enlarges (7), the vanes create a vacuum. As the air is pushed through the chamber and it becomes compressed, pressure is produced at the outlet port (6).

Features

- Single satge direct drive, carbon vane type Dry Rotary vane vacuum Pump.

- Compact, Reliable & easy maintenance

- Air cooled, completely oil free design.

- Ultimate vacuum : 25 "/Hg

Application Area

- Packaging machines

- Vacuum chuck

- Bottle Filling

- Blister Packing

- Filtration (With proper trap)

- Vacuum Sealing

- Conveying

- Evacuation

- Distillation (With proper trap)

Standard Acessories

-

Inlet Filter, Exhaust Silencer, Vibration pad, Vacuum gauge, Regulator and Motor

Technical Specifications

| MODEL | DISPLACEMENT (M3/hr) | VACUUM(Inch Hg.) | Power Hp | Wt.Kg |

|---|---|---|---|---|

| ADV-20 | 20 | 25 | 0.5 | 35 |

| ADV-30 | 30 | 25 | 1 | 55 |

| ADV-40 | 40 | 25 | 2 | 65 |

| ADV-60 | 60 | 25 | 3 | 85 |